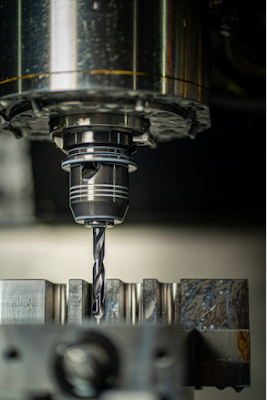

How to Ensure Accuracy and Precision in CNC Milling?

CNC milling is a highly dynamic and complex manufacturing process used to cut different materials like plastic, wood, aluminum, composites, steel, etc. The process of CNC milling is not easy and requires high precision to ensure accuracy and efficiency. Here are several key factors to help ensure both accuracy and precision in CNC milling: Temperature Control During CNC milling, especially when producing long runs, your machines will start producing heat. This can lead to distortion. To help prevent this from happening, you should make sure that you have good temperature controls in place around your machines. A good HVAC system can work wonders for keeping temperatures consistent, as can fans and vents that are designed for industrial use. Use Good CAM Software A well-maintained and modern CAM software program will help increase the efficiency of your CNC milling processes. If a manufacturer is using older CAD/CAM software, it can be difficult to achieve a high level of accuracy ...