Factors That Influence Your Weight Indicator System's Accuracy

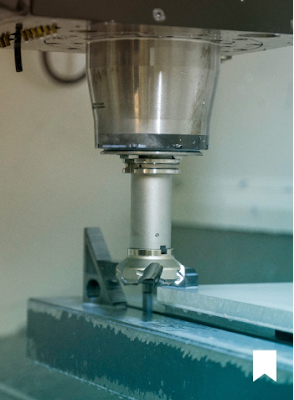

The accuracy of a weight indicator system depends on several factors. Even with high-quality weight indicator systems , certain aspects to consider substantially impact the system's precision . Using your knowledge can assist you in analyzing the significance of these factors, such as the nature and location of the application and other possible factors that may affect its accuracy. Following are factors that can affect your weight indicator system's accuracy: 1. Load Cell In any electronic weighing equipment, the load cell is the primary element. A load cell, also known as a transducer, directly converts mechanical force into an electronic signal. When a weight exerts a force on the load cell, it responds to this change. A compression mounted load cell, often located underneath the weighing system, contracts when applied with force . It subsequently generates an analog output signal proportionate to the applied weight, transmitted to a controller. A defective load cell can l