Benefits of CNC Machining Services

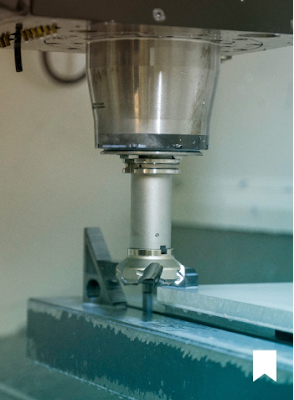

Computer Numerical Control (CNC) machining is an industrial manufacturing and production process that employs software and automation to regulate machine tools such as lathes, mills, grinders, and routers. This allows the preparation of molds into components through accurate removal of metal layers.

A CNC drilling instrument spins to remove sections of the component. In contrast, a lathe allows the contact of a drill bit with the material. Rotary tools are used in CNC milling to remove material from the machine.

Here are some vital benefits of CNC machining services:

1. Accuracy

CNC mills and lathes can copy a design and create identical products repeatedly. Every manufactured part will be the regardless of the manufacturing volume. CNC machined parts and items are highly accurate.

Many businesses require accurate finished parts, and CNC machining is one of the more precise manufacturing technologies. Many finished items require high manufacturing tolerance, a critical component in many sectors. Customers can benefit from selecting CNC machined parts manufactured with sublime precision and accuracy.

2. Efficiency

With just one programmer managing several CNC machines, productivity boosts dramatically compared to old-school milling and turning procedures. CNC lathes and milling machines can do the job faster and attain those manufacturing goals that people using conventional machinery may have difficulties accomplishing.

The time spent searching for properly machined parts is unproductive. CNC machining evaluates the requirements and makes the individual pieces required. Using a sturdy material will also ensure that the manufactured components are tough and durable.

With software that permits product simulation, CNC machining services save substantial time and money as there is no need for a physical model or prototype.

3. Adaptability

CNC machining allows the addition of functionality and beneficial features through software updates. It enables CNC machining services to keep up with the production standards and regulations, rather than becoming ineffective and obsolete. The evolution and enhancement of CNC machining services through software updates are capable of meeting the varying demands of customers.

4. Reliability

In contrast to human tool operators who can get sick and require regular breaks, CNC machines can operate endlessly and only need to shut down during maintenance.

5. Versatile Manufacturing

Manufacturing products having complex geometries and challenging angles are not a problem for CNC machining methods, which can operate in different angles and accommodate enormous quantities of metal or plastic parts in various shapes.

While many industrialists and tool operators still prefer manual lathing and milling techniques, modern-day CNC machining holds significant benefits. The development in CNC machining is paving the way to establish new industries.

Are you seeking exceptional CNC machining services? Contact Instruments provides excellent tooling designs and machining services to its customers. The reputed company also provides trash pump parts, load cells and pressure sensors, and drilling rig instrumentation for its customers.

Contact them to secure high-quality deflection and clipper weight indicators.

Comments

Post a Comment