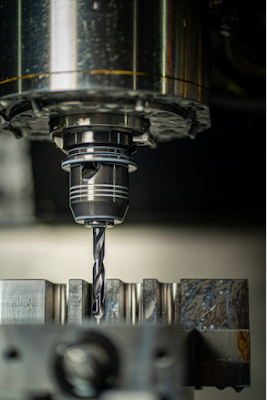

How to Ensure Accuracy and Precision in CNC Milling?

CNC milling is a highly dynamic and complex manufacturing process used to cut different materials like plastic, wood, aluminum, composites, steel, etc. The process of CNC milling is not easy and requires high precision to ensure accuracy and efficiency.

Here are several key factors to help ensure both accuracy and precision in CNC milling:

Temperature Control

During CNC milling, especially when producing long runs, your machines will start producing heat. This can lead to distortion. To help prevent this from happening, you should make sure that you have good temperature controls in place around your machines. A good HVAC system can work wonders for keeping temperatures consistent, as can fans and vents that are designed for industrial use.

Use Good CAM Software

A well-maintained and modern CAM software program will help increase the efficiency of your CNC milling processes. If a manufacturer is using older CAD/CAM software, it can be difficult to achieve a high level of accuracy because the tools may not have been designed for modern machines. Newer software programs have tools that are specifically designed for modern CNC mills and lathes, so they can take advantage of their capabilities fully.

Choose the Right CNC Milling Machine

It is important to choose a mill that will handle the type of machining you need with ease. Some machines are designed for specific applications. For instance, if you need to work on huge parts, you should go for a gantry-type mill instead of a bed mill. Also, consider how easy it will be to replace or repair worn-out parts.

Regular Maintenance

You should perform regular maintenance on your CNC milling machine to ensure that it remains accurate and precise at all times. Check the temperature of ball screws, couplings, and other components regularly using infrared thermometers. Apart from checking their temperatures, you should also lubricate these components regularly to prevent wear-and-tear issues that can affect accuracy and precision.

Get the Best CNC Machining Services

CNC milling has emerged as a go-to method for manufacturing components with accuracy and precision. Ensuring that this process happens without any hiccups is important to get perfectly accurate parts. Any mistakes in this process can result in inaccurate or inefficient parts that might need reworking or might even have to be scrapped.

This is why working with an experienced operator is key. We highly recommend Contact Instruments which serves clients across the globe and in a diverse range of industries. Their comprehensive product portfolio includes drilling instrumentation, custom cables, torque gauge, weight indicator systems, industrial gauges,mud pressure gauges, and other industrial applications to the global well-servicing market.

Contact them today for high-quality CNC machining services.

Comments

Post a Comment