How CAD/CAM Is Revolutionizing CNC Machines

Computer-aided design (CAD) and computer-aided manufacturing (CAM) equipment can be found in virtually every industry around the world. Many industrial floors are now devoid of human contact, with just ‘robots’ populating them.

The industry has been able to reduce labor costs while simultaneously producing higher-quality accuracy components that are free of human mistakes and less expensive, thanks to the introduction of Computer Numerical Control (CNC) technologies.

Let’s take a closer look.

A Quick Overview of CAD-CAM Software

Before we get into the benefits of CAD-CAM software, let’s take a look at how it works.

CAD

CAD stands for Computer-Aided Design. It consists of software and procedures used to build designs using computers. This frequently results in files needed later in the CAM procedure. This is the process of creating computer simulations based on certain 3D geometrical models that are seen on a computer display.

By adjusting parameters, these simulations may be readily modified. These technologies enable designers to observe items in several ways. They may also put these computer models to the test by modeling them in real-life scenarios.

CAM

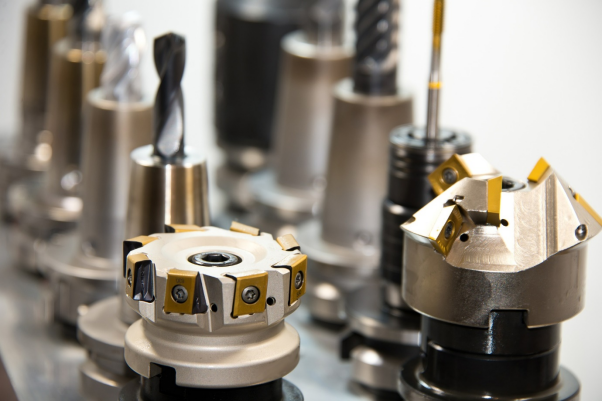

CAM stands for Computer-Aided Manufacturing. It refers to the different methods through which computers are employed to produce the things that people have planned, typically through the help of CAD. Much of the time is spent translating CAD data into shapes that can be utilized to drive CNC machines. These software programs are intended to operate and automate machinery.

CNC

The term CNC stands for Computer Numerical Control. It applies to the exact commands and directions sent to the CAM machines. This is usually in the form of G-code, which directs the device along specific pathways at proper speeds and inputs for the devices.

What Role Does CAD-CAM Systems Play in CNC Machining?

Quick Prototyping

The CAM guarantees this as one of the primary advantages. During the design process, the designers may quickly build prototypes. These prototypes may be used to test different components of the design.

Cost Saving

CAD-CAM applications tools allow users to examine the toolpath before cutting material, reducing material waste. This is especially suitable for systems involving costly metal alloys, complicated shapes, or material-intensive parts.

Another benefit is less material waste, which saves energy costs and lowers device maintenance.

Time-Saving

High-speed tool paths are guaranteed by all sophisticated CAM software, allowing machines to make larger cuts at faster rates.

Versatility in Design

CAD-CAM software ensures a wide range of design options because it makes it simple and quick to make specific design adjustments.

Contact Instruments is Canada’s market leader in OEM drilling instruments. To satisfy your requirements, we provide CNC machining, load cells, drill rigs, custom cables, and other industrial applications.

Contact us to learn more about how our goods and services may help you increase your company’s proficiency and productivity.

Comments

Post a Comment